Autonomous type cryostats

Laboratory research cryostats autonomous type designed to maintain the desired temperature in the 1.4 - 500 K (77 - 500 K) in the working area of the cryostat - thermostatic chamber - and in its design is liquid-flowing.

Kriostatuvannya samples in the range from 1.6 to 4.2 K shall support certain reduced pressure over the surface of boiling helium, which is immersed sample (incubation chamber) temperature control in the 4,2 - 500,0 K (80 - 500 K) by changing the feed rate of cryogen chamber temperature control and heating the cryogen. The change in temperature of the sample under these conditions is achieved by heat exchange helium gas flow (nitrogen) which passes through the incubation chamber and blowing like.

Nitrogen cryostats

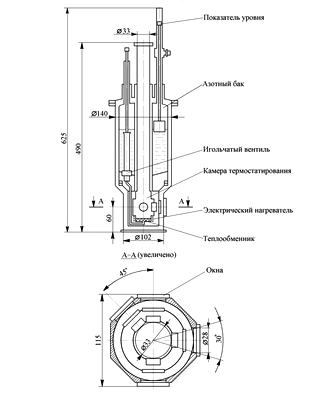

Inside the collapsible enclosure placed nitrogen tank with outboard radiation screen temperature control chamber and boot tube (mine). Nitrogen tank suspended from the lid of the case on three thin-walled tubes of the material with low thermal conductivity. Hanging Tubes nitrogen tank used to enter the tank needle valve, float level indicator liquid nitrogen to fill the liquid nitrogen tank . On top of all three tubes interconnected collector. In the cavity of the nitrogen tank located float krionasos node and nitrogen supply. Depending on the position of the valve hochastoho feed cryogen temperature control chamber from the tank by capillary enters either gaseous or liquid nitrogen evaporates in the heat exchanger.

In the center of the body of the cryostat is mine, ending the bottom chamber temperature control. Outside temperature control chamber soldered heat exchanger connected to a nitrogen supply tube. The camera thermostatic electric heater wound. Top of the screw shaft ends with vtulkoy prokladkoy, which by means of nut mounted crane. The space between the nitrogen tank and the outer shell is evacuated through the vacuum valve and maintained in the process built krionasosom.

Cryogen temperature is regulated by means of an electric current task in the heat exchanger. At temperatures of 80 - 350 K samples are in the flow of cryogenic gas that is directed upwards. Cryogenic gas flow is governed by a differential pressure regulator, which is located in manostati. The combined system controlling the flow of gas and the temperature of the heat exchanger allows to obtain highly accurate temperature maintenance and low cost of liquid cryogen. Temperatures from 80 K to 70 K are achieved cryogenic pumping gas. In this temperature range the sample immersed in liquid refrigerant. Replacing the sample through the upper flange shaft.

For the optical studies on the casing, the screen and the camera mounted thermostatic optical window.

To prevent the destruction of the cryostat with increasing pressure nitrogen tank installed safety valve, frangible disc which Torque at working pressure 7×10 4 Pa.

Series CRYOPT

Applications:- Optics

- Elektrooptyka

- Raman spectroscopy

- Spectroscopy

- Polyarizatsiyna optics

A 248 Optical Liquid-Flow cryostat

|

|

| Diameter shafts, mm | 33 |

| Optical inputs, location (Direction axes in cross-section), degrees | 0-90-180-315 |

| Material internal windows (optional) | Fused quartz, leykosapfir, ZnSe, CdTe, mylar |

| Internal windows (light appertura) mm | 16 |

| Nitrogen tank capacity, l | 2 |

| Refrigeration time, min. | 40 |

| Maximum flow of liquid helium, l/h at | |

| 80 К | 0,2 |

| 90 К | 0,16 |

| Temperature sensor | Silicon thermal diode |

| When replacing the sample, min. | 10 |

| The diameter of the specimen, mm | 33 |

| Weight (kg) | 6 |

.png)