As was shown

above, the use of solid

lubricants may be a very promising way, especially in micro-devices, where

conventional lubricants may often be ineffective or may even work like a glue.

In an ideal case of contact of two rigid crystalline incommensurate surfaces the

static frictional force is zero (moreover, the same

is true even for commensurate surfaces if they are not perfectly aligned).

Analogously, if the lubricant film has a crystalline structure and is confined

between two flat substrates with the ideal structure, the friction coefficient

in such perfect-sliding system may be as low as

μ ~ 10–3

to 10–2 or even lower. The critical

velocity of the transition from stick-slip to smooth sliding is also quite

small, vc~10–2c.

Unfortunately, such an ideal system can hardly be reproduced experimentally:

even specially prepared surfaces are not perfectly smooth on a mesoscopic scale,

and a lubricant has typically numerous structural defects. As a result, the

static frictional force fs is large enough, and the

solid lubricant will melt at the onset of sliding. Then, at stick, the film

solidifies back, but, again, either in an amorphous state or in a state with

many defects, because the cooling of the confined film is very rapid due to very

good thermal contact with the substrates. According to

simulation, in such a system one

finds μ > 0.1 and vc~ 0.1c, i.e., the tribological characteristics are even more

worse than those of liquid lubricants. In what follows we will explore whether

the system itself may approach the desired perfect-sliding regime for a suitable

choice of the solid lubricant. Indeed, the energy pumped into the system due to

external driving has to be converted into heat. Therefore, the effective

lubricant temperature T* must increase during sliding.

It is this increase of the temperature that leads to melting of the lubricant in

the melting-freezing mechanism of stick-slip. However, if T*

will remain lower than the melting temperature Tm, the lubricant film could remain solid and, at the same time, its structure may

become more ordered due to annealing of structural defects, especially if T* will be close to Tm. Because

Tm is determined by the interactions within the lubricant, one may play with the

parameters of interaction looking for a situation when Tm

is

close to (but higher than) T*. Below we show that, indeed, a

suitable choice of the parameters may lead to the desired self-ordering of the

lubricant and consequently to the low values of the frictional forces.

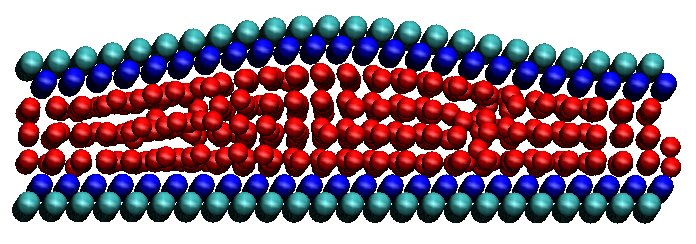

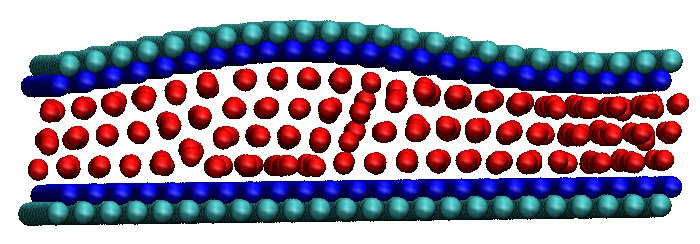

Sliding-induced ordering of the

Nl=1 system for vspring= 0.1

|

|

|

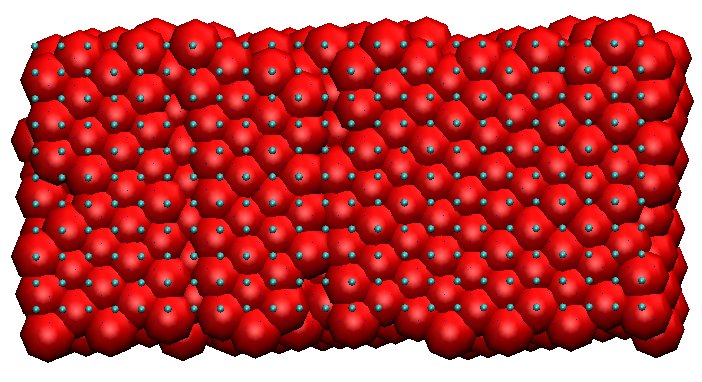

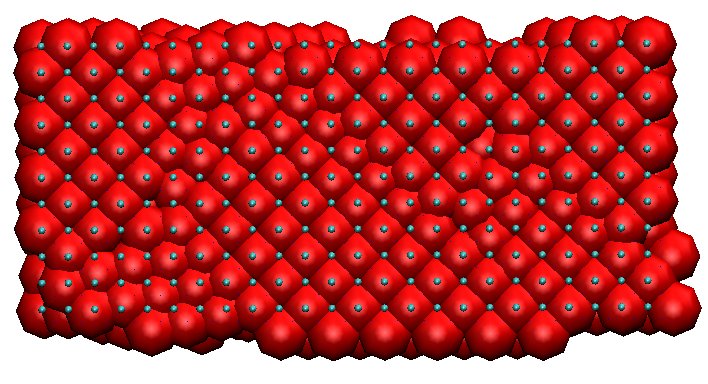

Configuration before

self-ordering |

|

|

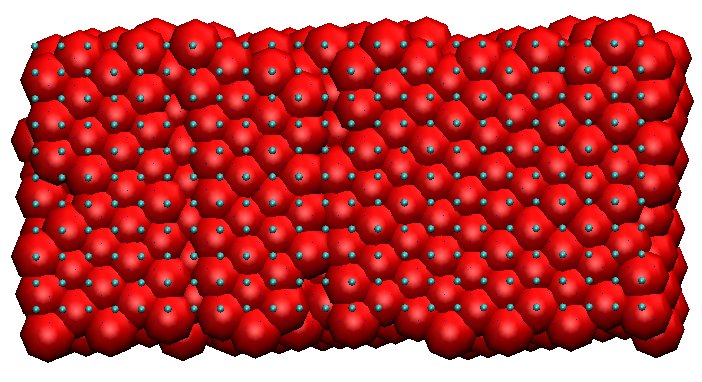

Configuration after

self-ordering |

|

| |

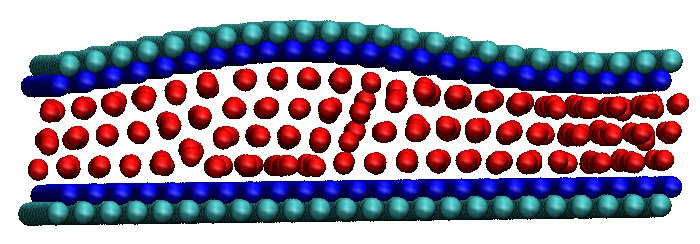

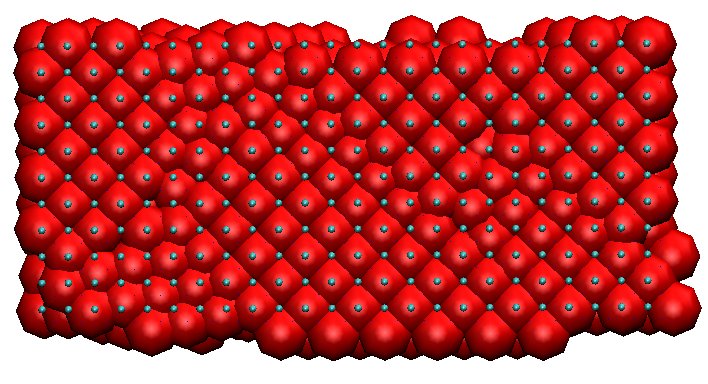

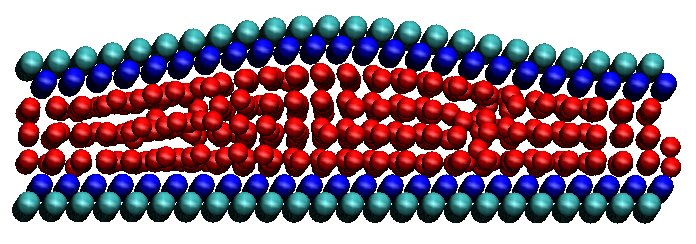

Sliding-induced ordering of the

Nl=3 system for vspring= 0.3 &

movie (avi 1.5 Mb)

Sliding-induced ordering of the

Nl=3 system with Vll= 0.5 (so that

Vll/Vsl= 1.5) and the curved top substrate

for vspring= 0.1

| Configurations: |

| before self-ordering (commensurate) |

after self-ordering (incommensurate) |

|

|

|

|

| movie

(mpeg 7.2 Mb) |

movie

(mpeg 9 Mb) |

| full

movie (mpeg 15 Mb) |

Figure:

Static fs and kinetic fk

frictional forces for three values of the driving velocity (vs=

0.1, 0.3 and 1 as shown in legend) as functions of the interaction amplitude

Vll in semi-logarithmic scale. The error bars

show deviation of the simulation results in different runs.

From this figure we

can observe two clear-cut features: First, as one can judge from the dependence

of fk on vs, the

mechanism of the stick-slip motion changes from the melting-freezing to the

inertia mechanism at Vll ≈

0.5, i.e., for Vll/Vsl ≈

1.5. Most importantly, we observe that for Vll≈ 0.8

the kinetic frictional force fk

achieves a minimum as low as fk ≈ 10–4

to 10–3. The friction coefficient in

this case takes values of order μ < 10–2

which are more than one order of magnitude lower than those attainable with

conventional liquid lubricants. Namely, for the optimum value of

the interaction,

Vll= 0.75, at v = 0.03 we get

smooth sliding with fkinetic≈ 10–4,

so that

µ ≈10–3 (see

movie mpeg 3.3 Mb).

Conclusion

It exists an optimal choice of the

strength of interatomic interaction Vll within the

lubricant, that leads to the minimization of the kinetic friction as well as to

the low critical velocity of the stick-slip to smooth-sliding transition. The

optimal value of Vll should be high enough (relatively

to the amplitude Vsl of the interaction of

lubricant atoms with the substrates) so that the lubricant remains in the solid

state during sliding. At the same time, the value of Vll

should be not too high, in order to allow annealing of the structural defects in

the lubricant. For the parameters used in the simulations, the optimum was

achieved at Vll ≈ 2.5Vsl.

Last updated on April 1, 2004 by O.Braun. Translated from

LATEX by

TTH