Definition: The word tribology is derived from the Greek word tribos, meaning rubbing ("to rub"); thus, a direct translation of "tribology" is "the science of rubbing". However, now tribology incorporates also the studies of adhesion, contact formation, wear, fracture, lubrication, nanoindentation and, first of all, friction.

Historical remarks: The macroscopic laws of the classical (macroscopic) friction were found by da Vinci, Amontons, Euler and Coulomb.

Leonardo da Vinci (1452-1519) made experiments on an inclined plane. He found that friction is independent on the area of contact.

The law of Leonardo appears quite bizarre: Intuitively one would expect the friction force to be proportional to the area of contact. The paradox was resolved by Bowden and Tabor (~1950, see below), distinguishing between the real area of contact and the geometric (visible) area of contact. The real area of contact is only a small fraction of the visible area of contact.

Guillaume Amontons (1663-1705) have done experiments on a horizontal surface and measured the friction force with a spring. He observed that if double or triple the weight of the log, the friction is also doubled or tripled respectively. Thus, friction is proportional to the normal force (load) (and independent on the area of contact). Amontons called the proportional factor friction constant.

Leonard Euler (1707-1783) pointed that one has to distinguish between the static and kinetic friction: da Vinci tested the static friction, while Amontons dealt with the kinetic friction.

Charles Coulomb (1736-1806) measured the kinetic friction for different speeds and found that friction is independent on the velocity.

In one type of problems we have to maximize friction, for example,

(a) at ancient times (200,000 BC) – frictional heating in the lighting of fires by rubbing wood on wood;

(b) nowadays

– pins (bolts

etc., the static friction) or braking (kinetic friction between the car tires and the road).

(a) Egyptians (2,400 BC) used water to lubricate wooden sledges used to transport large stones to build the pyramids;

(b) nowadays – in machines, e.g., car engines. An example (from Persson's book): in USA friction takes away about 6% of the gross national product

Hydrodynamic (fluid) lubrication (Reynolds 1886)

– for a (macroscopically) thick liquid

layer (e.g.,

use Navier-Stokes equations with appropriate boundary conditions (typically stick = locked);

the friction is determined mainly by the viscosity of the liquid lubricant;

an example (from Persson's book): Which lubricant is better – oil (with high viscosity) or water? A drop of water between clean hands does not make the hands slip easily over each other, while a drop of oil does. Why? The fluid is squeezed out from the contact area, but this process will take a long time if the viscosity is large.

Boundary lubrication – for a thin (few Angström) lubricant film, e.g., if the lubricant was squeezed out from the contact area

the friction is typically much higher, e.g., by a factor of 102, as compared with the hydrodynamic lubrication;

the friction mainly depends not on lubricant viscosity but on the chemical composition of the fluid; usually the better lubricant corresponds to a fluid that is adsorbed by the solid substrates.

At stop/start, (almost) always the regime of boundary lubrication occurs. In what follows we consider the boundary lubrication only.

(1) Standard technique (Bowden and Tabor 1950; Rabinowicz 1965; surface forces apparatus by Bhusham, Israelachvili, Landman, Granick; experiments with paper on paper by Heslot et al)

|

|

(2) STM/AFM/FFM: scanning tunneling microscope (Gerd Binnig & Heinrich Rohrer 1981, Nobel Price 1986) for conducting surfaces, and atomic-force microscope (Binnig et al 1985) for dielectric surfaces – measure surface topography; friction-force microscope (Mate et al 1987) measures forces transverse to the surface

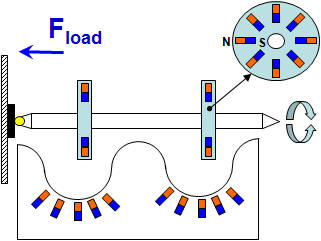

(4) Levitating tribometer (O.A. Marchenko & V.S. Kulik, Institute of Physics NASU; see movie)

|

|

|

(5) Molecular dynamics (MD)

μ

≡ Ffriction/Fload

≈ constant, and μ is less than or about of 1 (Amontons 1699) → real

(actual) contact area

Let Pload(real) = PloadA/Areal be the real pressure at the contact. Then:

at low Pload(real) < Pyield (elastic regime) the number of contacts increases with load

at high Pload(real) > Pyield (plastic regime) the area of one contact increases (linearly) with load

μkinetic< or << μstatic, and μkinetic is approximately independent of the driving velocity v

Stick-slip motion ↔ smooth sliding

stick-slip motion for soft systems and/or low velocities

smooth sliding for stiff machines and/or high velocities

"Memory/age" effects: frictional

forces depend on the previous dynamical history of the solid-solid contact,

e.g.,

Full (large-scale) MD simulation showed that the lubricant structure may be

liquid (low kinetic friction, fstatic=0)

amorphous (high frictions)

solid (may be very low kinetic friction = superlubricity)

Contacts / junctions / asperities:

areas of real atomic contact between the two solids are small

the contacts are randomly distributed in space over the area of apparent contact

a typical contact size is 1 to 10 μm (may be measured optically)

An example (from Persson's book):

Put a steel cube of

10 × 10 × 10 cm3 on a steel table. Taking

Forces are of atomic-scale value – close to the plasticity threshold. Estimation:

a force per atom is f

~ 1 eV / 1

STM/AFM/FFM: area of one contact

is A ~ 3 Å2; taking

the hardness of the contacts is (much) larger than that of the material itself, because there are no dislocations in the (very small) stressed volume

thus, (almost) always a deformation (either elastic or plastic) occurs at the

contacts; this also explains Amontons law (Bowden and Tabor 1950):

(Almost) always there is a lubricant between the solids (called "third bodies" by tribologists): either a (specially chosen) lubricant film, or grease (oil), or dust, or wear debris produced by sliding, or water or/and a thin layer of hydrocarbon etc. adsorbed from air. Thus, the frictional force is almost entirely determined by the force required to shear the lubricant film itself.

(Almost) always the lubricant and the solids are "incommensurate":

the lattice constants do not coincide in a general case

the angles: the direction of sliding is generally at some angle to the surface lattice, and

the two surface lattices are not generally in registry

but the situation is not so trivial – often the lubricant atoms are "glued" (grafted) to the substrates (to avoid the flow of the lubricant out from the contact region), thus in fact we typically have an interface between the "glued" lubricant layer and other lubricant layers, thus the interface may be commensurate.

A thin film (less than 10 molecular diameters) is (almost) always layered, because the plates induce crystalline order in the film (solidify / freeze the lubricant; Thompson et al 1995). Moreover, when the lubricant thickness is less than three layers, most films behave like solid (glass-like in most cases, although may be ordered for relatively simple lubricant molecules).

See also an interesting tutorial with movies at Nano-World - a Swiss Virtual Campus Project

Assume that the yield stress τs at the contact is linearly coupled with the local pressure p,

|

Then, integrating over the area of real contact, we obtain

|

and

|

where <p> = Fload/Areal. Amontons' law operates if either <p> >> τ0, or if <p> is constant, the latter holds for the ideally plastic surfaces (when <p> = Pyield) as well as for elastic surfaces (Volmer and Natterman 1997: real surfaces are self-affine fractals, thus as Fload increase, the old contacts are expanding and new contacts are created). Finally, the real area of contact must become equal to the apparent area, and Amontons' law will not operate. It is so for rubber but not for steel – a machine would be destroyed earlier.

| In a typical experiment as well as in real machines, a spring is attached to the slider (even if there is no spring, the elasticity of the block plays the same role). The free end of the spring moves with a velocity vspring, and the force in the spring is registered. |

|

|

low velocity &/or soft system high velocity &/or stiff system |

|

|

Experiment: the behavior depends on the values vspring and kspring. The smooth sliding is observed if the spring is stiff enough, and/or if the velocity is high enough. Otherwise, the stick-slip motion is observed. During stick, the elastic energy is pumped into the system by the driving device; during slip, this elastic energy is released into kinetic energy, and eventually dissipated as heat.

|

|

Note: if one assumes that the frictional force depends on the instantaneous velocity only, ffric= f(v), then the boundary separating two regimes corresponds to the vertical line in the (vspring, kspring) plane (i.e., the critical velocity is independent of kspring), that is wrong. Thus, "memory" effects must be included.

|

(a nice applet written by F.-J. Elmer clearly demonstrates stick-slip and smooth motion)

The phenomenological model of the transition "stick-slip motion « smooth sliding" has been developed by Heslot et al 1994, Baumberger et al 1994, and Persson 1997. The model is based on the assumption that the static frictional force depends on the time of stationary contact. For example, if the sliding-to-locked transition has occur at t=0, then the static frictional force will evolve as

|

(*) |

|

Qualitatively (Persson): In case (a) the spring force increases faster with t than the initial linear increase of the static frictional force; hence the motion of the slider will not stop and no stick-slip motion will occur; In case (b) the spring force will be smaller than the static frictional force until t reaches the value t1 at which time slip starts; hence stick-slip motion will occur. Thus, the critical velocity is determined by the initial slope of the dependence fs(t), vc ~ kspring–1 dfs(t)/dt|t=0

|

|

|

|

|

(**) |

Zero-dimensional model – one atom in the periodic substrate potential: the rigid bottom substrate (external sinusoidal potential) + one atom + the dc force is applied directly to the atom + Langevin motion equation + underdamped external friction

One-dimensional models:

|

Tomlinson model |

|

|

|

|

(nice applets for the Tomlinson model and the dc driven FK model were written by F.-J. Elmer)

More complicated models:

Tomlinson + FK (Elmer et al)

Two FK chains (J.Röder et al)

The FK chain between two external sinusoidal potentials (Rozman et al)

Random substrate/springs (overdamped FK model, Cule and Hwa 1996) → directed percolation

Two-dimensional models

2D(||) models: 2D layer of atoms on the 2D periodic substrate. Variants:

Springs and balls models: dislocation lines, instabilities

Scalar anisotropic 2D model: system of coupled 1D FK chains

Vector anisotropic 2D model: zigzag kinks

Vector isotropic 2D model (Persson 1993, 1994; our simulation)

2D(┴) model (Hammerberg et al): creation of dislocations at the interface; cracks

Last updated on October 15, 2008 by Oleg Braun. Translated from LATEX by TTH